Post overview

- New Solidworks design

- Facing vibration

- Fabrication

- Installation

- Battery and Drawer

- What’s next

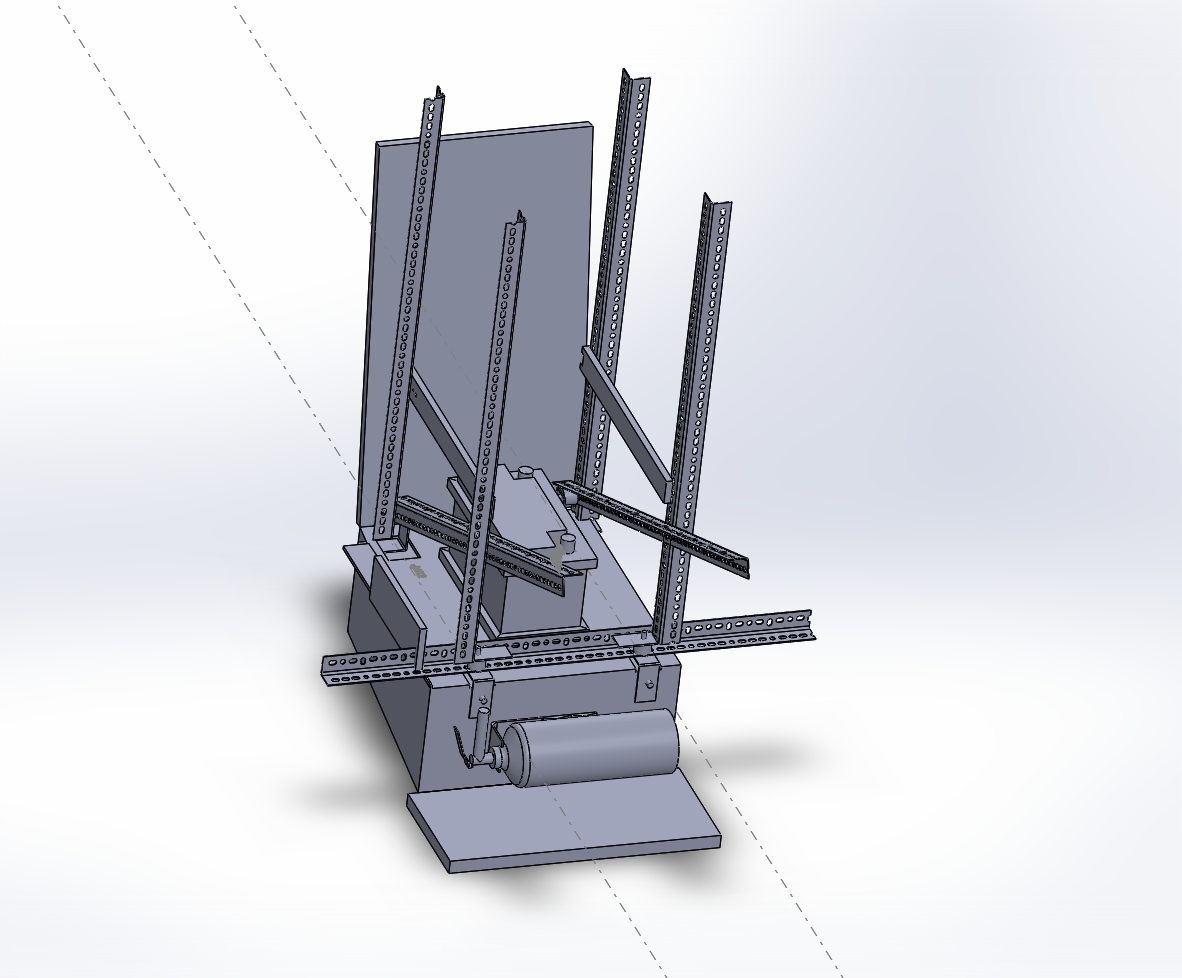

New Solidworks design

Recall that I posted the initial solidworks design of Rack frame design on the rear seat. However, until I bought angle irons, entered fabrication lab and started to punch the drill hole, I found that I did the first solidworks design like garbage. Thus I re-do the design, make all the pieces almost the same as the real one.

Facing vibration

A running car generates both low frequency vibration from suspension and high frequency vibration from engine. Sometimes it will also triggers so-called high G vibration, simply when you pass a bump. So vibration isolation is critical for protecting the electrical equipments, and help to stop the physical structures from dismantling due to increased inertial force under high G condition.

Vibration lossnening is another problem that I need to solve. According to video Plain net self-lossening, bolts will soon be lossnening in short time. (No date for how short time and no data for the frequency and amplitude of vibration, but a qualitative claim)

As an experimental solution, I bought self-lock bolts and lock nuts. Let’s what’s going on after days and months.

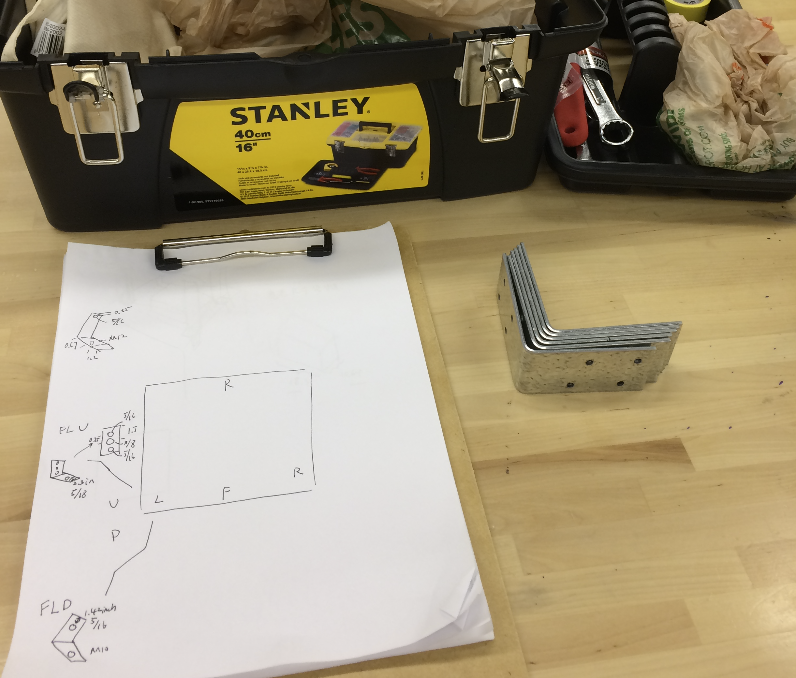

Fabrication

Lucky, I took safety training session before so I can use Fabrication lab in my university.

Lucky, I took safety training session before so I can use Fabrication lab in my university.

Following the Solidworks design, I did the following jobs in fabrication lab:

- Drill holes on angle iron

- Cut the angle iron to fit the structure

- Cut steel plate to mount ball slide rack

- Cut support components

Installation

Because I did the fabrication job in three days, I installed the whole frame until I fabricated all the parts. One thing that may need to pay attention is, it is better to fasten nuts using torque wrench, with recommanded torque. Over tied fastening may damage the screw teeth.

Battery and Drawer

A large capacity auxiliary battery is necessary to keep central computer, Surveillance camera, router/switch, sensors and network work when the car is standby, and this auxiliary battery is also the power of high power equipments including Manipulators on the roof, battery charger for UAV carrier, and radar, in the next stage. Recall that the Project:Heron is still in the stage 1.

What’s next

The next step is installing fundamental electricities, including battery isolator, fuses, switchs, lights and others.