Post overview

- We bought a 3D printer!

- What problems we have?

- 3D printer helped us

- Some details

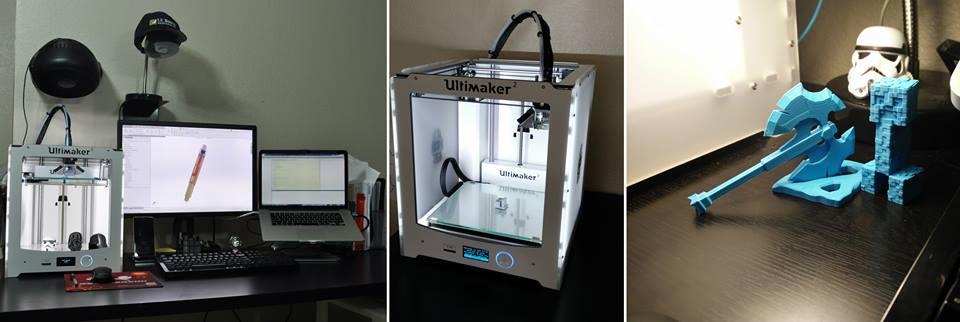

We bought a Ultimaker 2!

My partner, Yunan, watched for it over two years. As mechanical engineering student, having a well-made 3D printer is all his dream in the past two years.

After a short discussion, we bought an Ultimaker 2 3D printer. Not for entertainments, but for boosting our design in quick structure fabric and prototyping.

What problem we have?

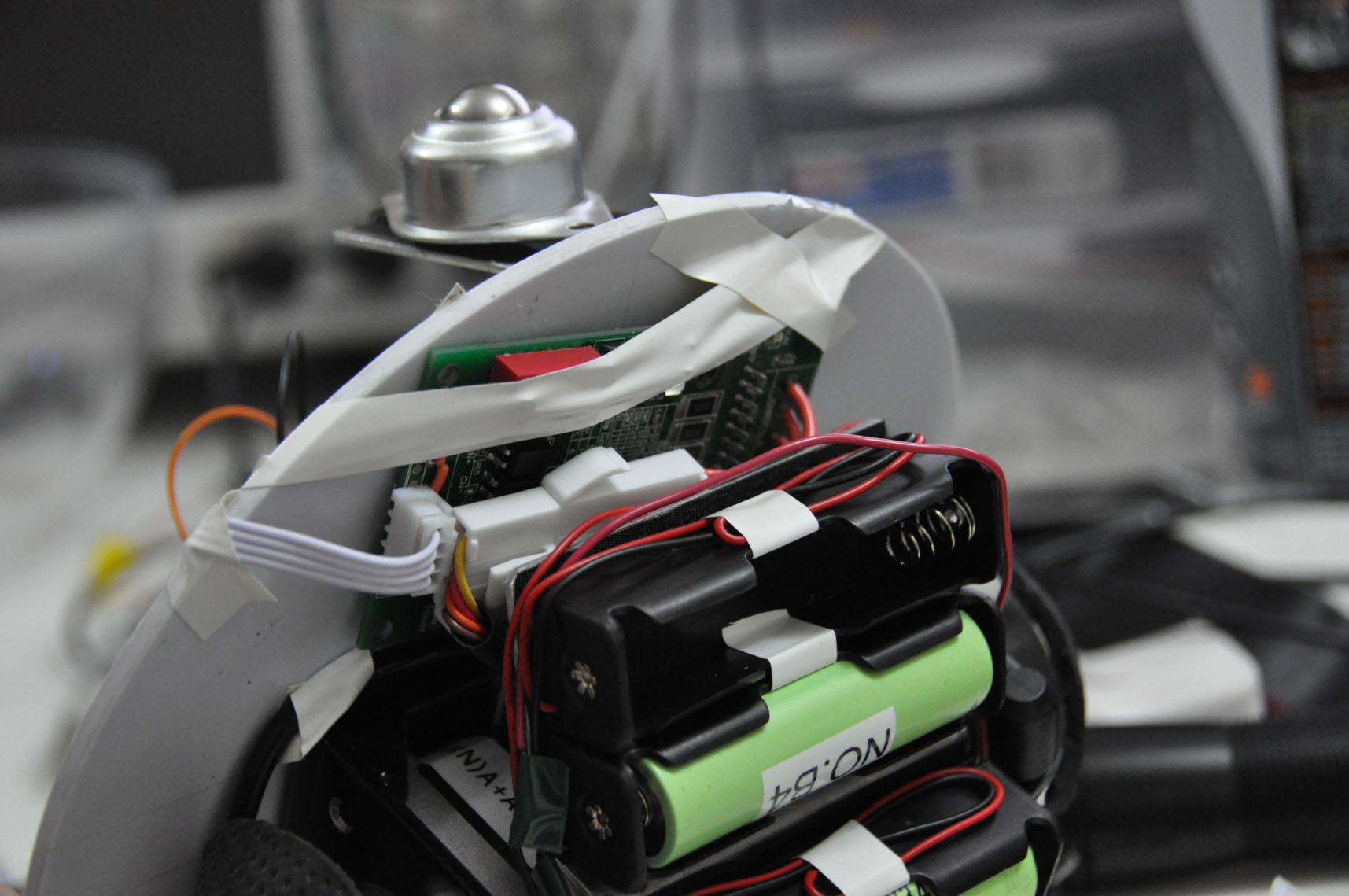

During Naughty Ball project, we have encountered problem on how to fix parts’s position. Our naughty ball’s structure is fiarely simple: a big ciruclar plane in the middle, divided the sphere space into two parts. We mount batteries, motors and motor drivers on downstairs, and we mount IR cameras, Beaglebone black, regulator, and etc. on the upstairs. However, because we have not freeze our design, so we cannot just drill holes on the center plane to fix the position, which will make it impossible to change design or add new devices like Xbee, in the future. The temporary solution is using tape, but absolutely, this is not a good idea.

3D printer helped us

But all the problems, were solved after 3D printer coming to us.

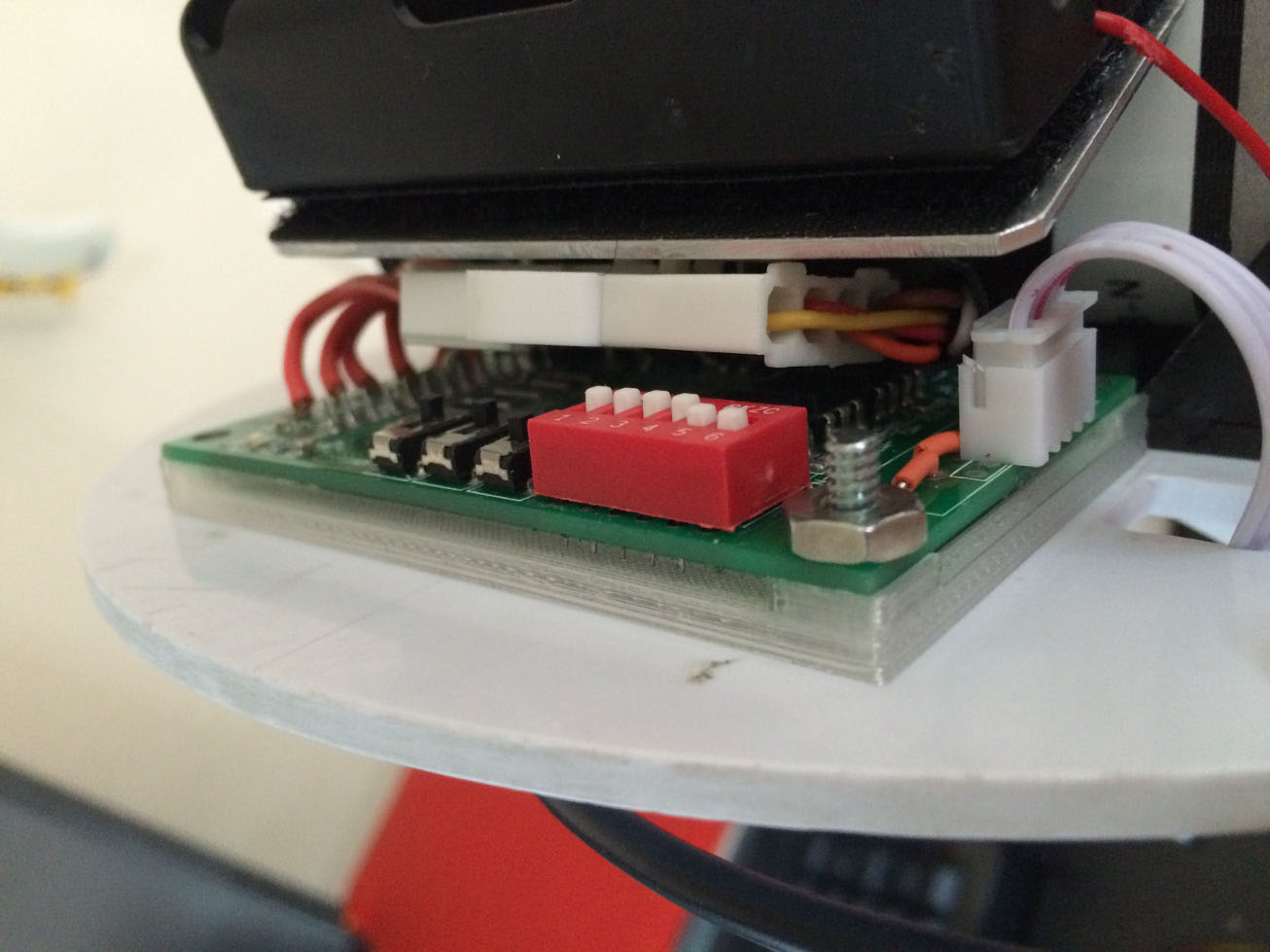

For downstairs, we used Solidworks to design a frame to hold driver board:

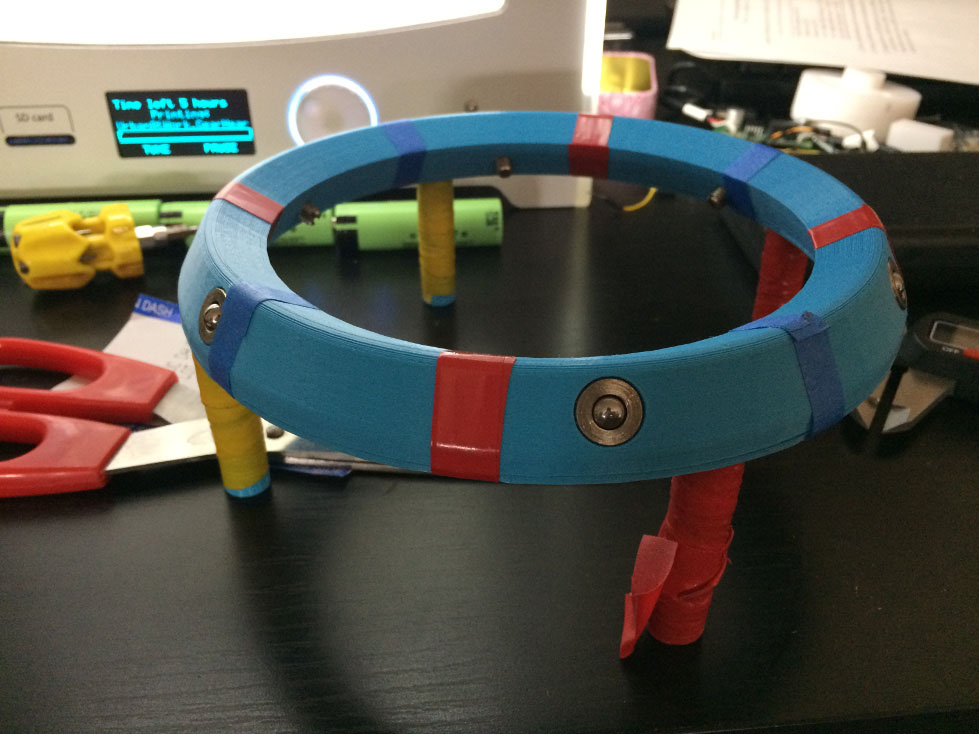

For upstiars, we printed a big circle structure to support ball-transfer units.

License

Our Project: NaughtyBall has reached end of winter quarter 2015, but we will continually work on it until the day it become the one that we like.